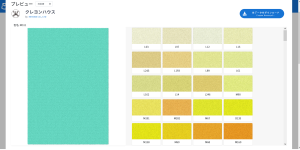

100% biomass dyeable fiber 【Re:Natuur】

A fiber made from modified polylactic acid (PLA) compound developed by Bioworks Co.

CO2 emissions from the fashion industry continue to increase, and are expected to reach approximately 2.08 billion tons worldwide by 2030.

The raw material for polylactic acid (PLA) fiber is sugar cane, which is carbon neutral and does not increase CO2 emissions.

However, due to the nature of the resin, it has rarely been used in the fashion industry.

Bioworks’ modified PLA has improved heat resistance, durability, and elasticity.

We will continue to contribute to a decarbonized society with 100% plant-derived fibers that are both functional and environmentally friendly.

biomass = carbon neutral

Although it emits CO2 both in production and in incineration, it emits about 43% less CO2 than polyester.

Furthermore, CO2 is absorbed through photosynthesis during the cultivation of sugar cane to make PLA.

As long as the same amount of sugar cane continues to be cultivated, virtually no CO2 is added.

It is possible to circulate CO2 in a shorter cycle than forests.

Features of “PlaX”, a Next-generation PLA Resin

In addition to fibers, bioplastics are understood to be environmentally friendly, but they are difficult to handle and unfortunately are not used in many fields.

For example, in injection molding, conventional modified polylactic acid (PLA) can hardly crystallize, and the only way is to slow down the cooling rate (increase the cooling time). On the other hand, PlaX with Bioworks’ additives has succeeded in significantly increasing the crystallization speed through a completely new crystallization promotion mechanism. As a result, it can be processed in the same molding cycle as general purpose resins. Also, it can be molded in molds at temperatures below 100 degrees Celsius, which allows water temperature to be controlled, so it can be used at any manufacturing facility.

“The PlaX”technology will enable a wider range of applications, including films and molded products other than fibers.